Vibration-Acceleration Testing

Vibration-centrifuge testing can simulate high centrifugal acceleration and vibration stress, more closely resembling the complex mechanical environment of actual space operations. Combined vibration-centrifuge testing is primarily used to verify structural strength, inspect the durability and reliability of spacecraft and their components under design loads, and evaluate system performance stability. It is particularly useful for testing electronic equipment and mechanical systems under various operating conditions, identifying potential failure modes and weaknesses, improving mission reliability, and optimizing design parameters.

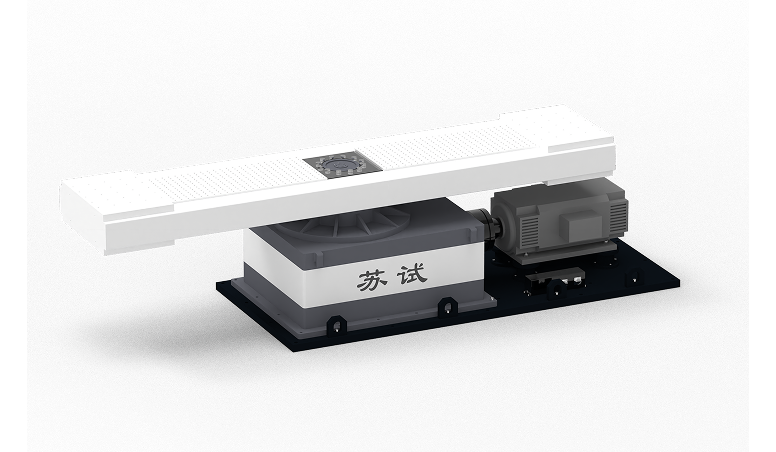

The laboratory's combined vibration-centrifuge system mainly consists of an electrodynamic shaker body and a swing-arm centrifuge. The shaker's armature uses a frameless coil winding technique, ensuring it is lightweight, rigid, and has a high natural frequency. The lower part of the armature is supported by air springs, and it is guided by two sets of guide wheels at the top and bottom, resulting in good waveform, high vibration accuracy, and low acceleration distortion on the working table.

The swing-arm centrifuge components mainly include a base, motor, gear reducer, main shaft, electrical slip rings, rotating arm, counterweights, platform, and speed measurement device.

Vibration testing, centrifugal acceleration testing, combined vibration-centrifugal acceleration testing, etc.

Combined Vibration-Centrifuge Test System Equipment Parameters:

1) Frequency Range: (5-4,000) Hz;

2) Max Acceleration: 50 g;

3) Max Displacement: 25 mm;

4) Rated Thrust: 9.8 kN;

5) Max Centrifugal Acceleration: 20 g;

6) Rotational Speed: 120 rpm;

7) Arm Length: 2.5 m;