Component & Module Product Testing

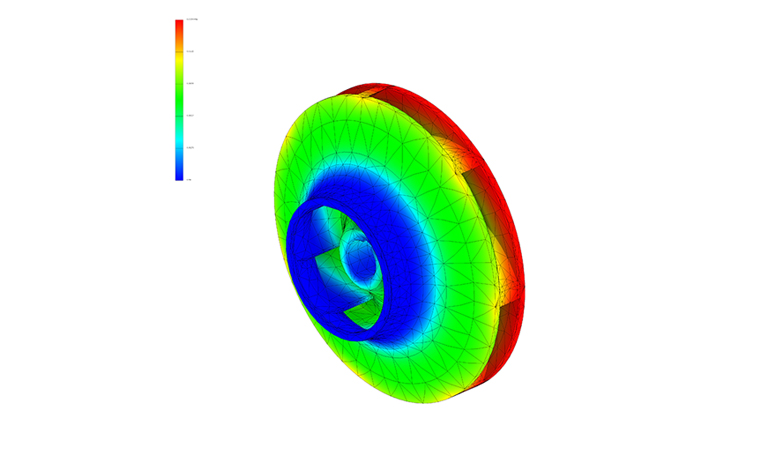

Aerospace components and modules mainly include electronic components, structural parts, sensors and instruments, and communication system components. These components and modules must undergo rigorous testing and certification to ensure their performance and reliability in extreme environments. The high requirements for quality and performance of components and modules in the aerospace field ensure flight safety and control maintenance costs. Test items include material testing and environmental safety testing.

Environmental Tests: Vibration, shock, shock response spectrum, drop, acceleration, high temperature, high-temperature storage, low temperature, low-temperature storage, constant damp heat, salt spray, sand and dust, waterproof, fungus, corrosion, thermal vacuum, etc.

EMC Tests: Radiated emissions, conducted emissions, radiated radio-frequency electromagnetic field immunity, electrostatic discharge immunity, pulsed magnetic field immunity, etc.

Material Tests: Static mechanical properties of materials, dynamic mechanical properties of materials, metal material analysis, polymer material testing, etc.

Component Tests: Electrical testing, destructive physical analysis (DPA), board-level/solder joint reliability verification, operational life test verification, etc.

RTCA-DO-160G Environmental Conditions and Test Procedures for Airborne Equipment, etc.

CNAS, etc.