Electrical & Electronic Equipment

The laboratory is equipped with advanced testing equipment such as vibration and shock test benches, a 500T bearing system, MTS multi-channel fatigue test systems, over 2000 channels of strain acquisition systems, and non-destructive testing equipment. Our testing capabilities cover environmental adaptability, reliability assessment, vibration characteristics, static load fatigue, and life assessment, providing one-stop technical services.

As the vehicle operates, electrical and electronic equipment is subjected to complex stress loads, including mechanical stresses like vibration and shock, electrical stresses, and environmental stresses such as high/low temperature, damp heat, salt spray, and fungus. The laboratory has configured and built complete testing equipment according to domestic and industry standards, possessing comprehensive assessment capabilities from environmental to performance tests. We can also simulate and assess the actual working conditions of the tested products in the laboratory to verify their operational reliability and ensure their performance meets standard requirements.

Environmental Tests: Vibration, shock, fungus, salt spray, etc.

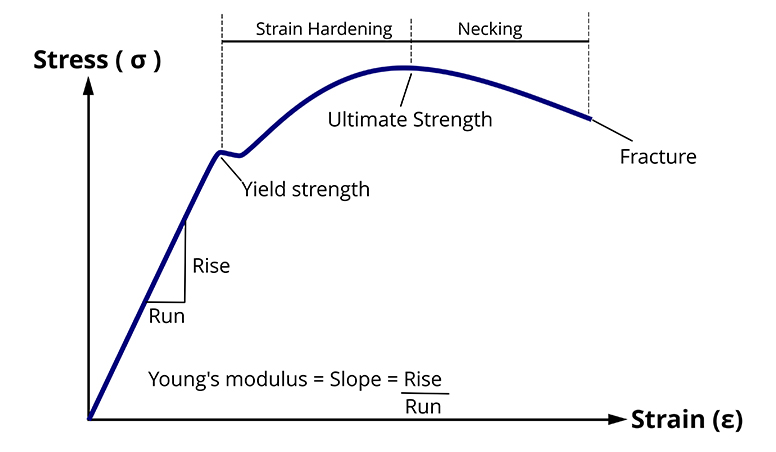

Performance Tests: Working load, ultimate load, fatigue life assessment, etc.

Main Circuit Electricals: Traction motors, inverters, air compressor units, etc., for train traction and braking.

Auxiliary Circuit Electricals: Batteries, overvoltage protection resistors, etc., for emergency power supply and energy recovery.

Control Circuit Electricals: Signal processing and equipment control, such as main control circuits, auxiliary control circuits, etc.

CNAS