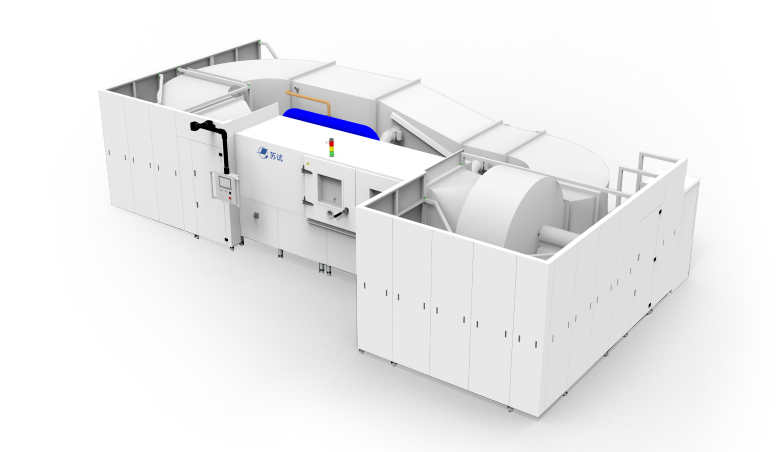

Airborne Equipment Testing

Airborne equipment refers to all instruments, systems, and subsystems installed on aircraft or other aerial vehicles for flight control, navigation, communication, flight status monitoring, ensuring flight safety, improving flight efficiency, and performing specific tasks. The testing of airborne equipment is mainly aimed at improving flight safety, reducing maintenance costs, promoting technological innovation, and enhancing maintenance efficiency. Specific items include material testing, safety testing, EMC testing, environmental safety testing, and reliability and failure analysis of electronic and electrical products.

Environmental Tests: Vibration, shock, shock response spectrum, drop, acceleration, high temperature, high-temperature storage, low temperature, low-temperature storage, constant damp heat, salt spray, sand and dust, waterproof, fungus, corrosion, thermal vacuum, etc.

EMC Tests: Radiated emissions, conducted emissions, radiated radio-frequency electromagnetic field immunity, electrostatic discharge immunity, pulsed magnetic field immunity, etc.

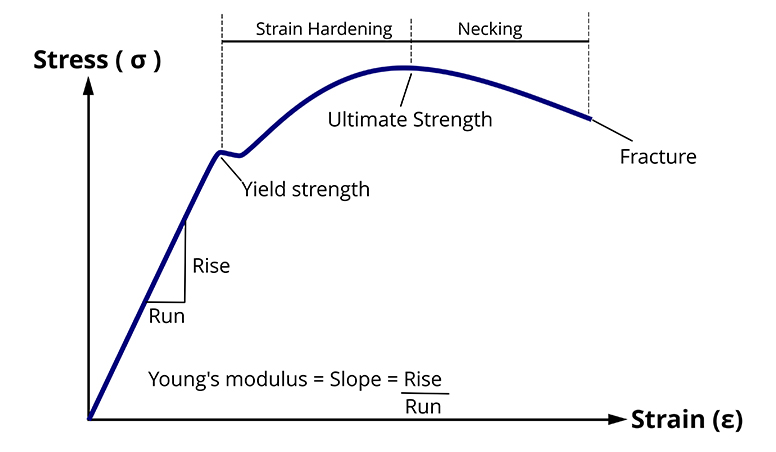

Performance Tests: Static load and fatigue performance, modal testing, rotational performance, airborne equipment electrical performance, etc.

Material Tests: Static mechanical properties of materials, dynamic mechanical properties of materials, metal material analysis, polymer material testing, etc.

RTCA-DO-160G Environmental Conditions and Test Procedures for Airborne Equipment, etc.

CNAS, etc.