UAV Testing

The necessity of reliability testing for UAVs (Unmanned Aerial Vehicles) is mainly reflected in ensuring flight safety, enhancing adaptability to extreme environments, ensuring user experience and performance stability, complying with regulations and industry standards, extending product life, and promoting technological iteration. By simulating complex environmental conditions such as high/low temperature, high humidity, salt spray, vibration, acceleration, and shock, the laboratory tests the stability and durability of UAVs in extreme scenarios, ensuring they can operate reliably in harsh climates or special missions.

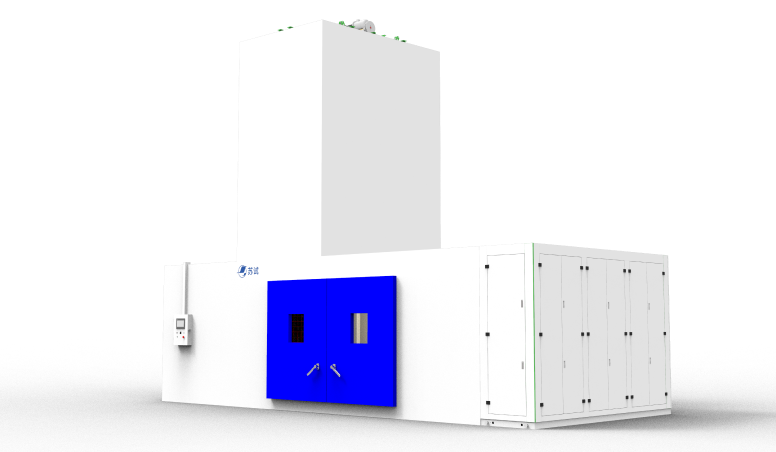

Environmental Tests: Vibration, shock, shock response spectrum, drop, acceleration, high/low temperature, damp heat, salt spray, sand and dust, waterproof, fungus, corrosion, temperature-altitude, icing, etc.

EMC Tests: Radiated emissions, conducted emissions, radiated radio-frequency electromagnetic field immunity, electrostatic discharge immunity, pulsed magnetic field immunity, etc.

Material Tests: Static mechanical properties of materials, dynamic mechanical properties of materials, metal material analysis, polymer material testing, etc.

RTCA-DO-160G Environmental conditions and test procedures for airborne equipment, etc.

CNAS, etc.