Motor Electrical Performance Testing

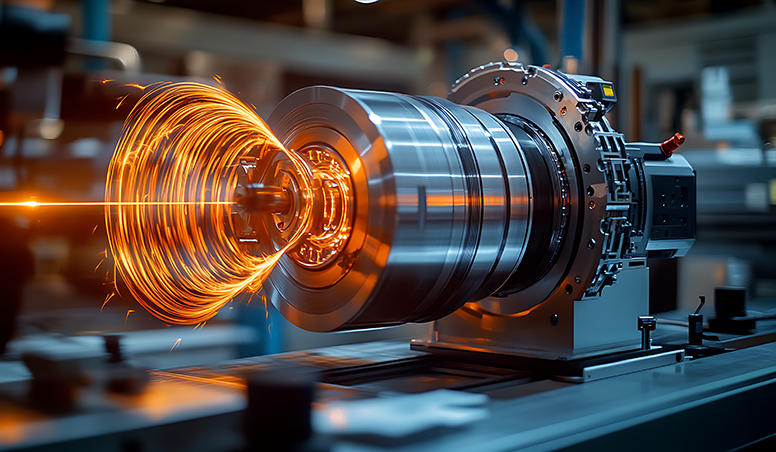

Electrical performance tests mainly include temperature rise test, no-load test, load test, maximum and minimum torque test, starting torque and starting current test, etc. The main purpose of these tests is to examine the thermal rating, output capability, service life, and adaptability of the tested motor under abnormal working conditions.

Input-Output Characteristics Test: Operating voltage range, 30-minute continuous torque, continuous power, peak torque, peak power, maximum operating speed, drive motor system efficiency, control accuracy, locked-rotor torque, regenerative braking characteristics.

Safety Test: Potential equalization, protection functions, DC bus capacitor discharge time.

Adaptability Test under Abnormal Working Conditions: Overvoltage test, overcurrent test, over-torque test, lightning surge test, cycle drop test, etc.

Durability Test: Performance durability test.

The laboratory is equipped with an imported German AKH 16,000rpm dynamometer test system, with a maximum speed of up to 16,000rpm, rated speed of 4,773rpm, rated torque of 500Nm, peak torque of 600Nm, and rated power of 250Kw; a four-channel Yokogawa WT5,000 power analyzer; and a 1,400L temperature and humidity environmental chamber.

Dynamometer Test Bench Parameters:

Maximum speed: 16,000rpm

Peak torque: 600Nm

Peak power: 250Kw

Temperature control range: -40°C to +150°C

Humidity control range: -20%RH to 98%RH

Power supply continuous power: 300kW

Supply voltage range: 24-1,000VDC

Current output range: 1,000A

Power measurement accuracy: ±0.01%

Current sensor accuracy: ±0.005%

Current sensor measurement range: 0 to 1,000A