Rotational Performance Testing

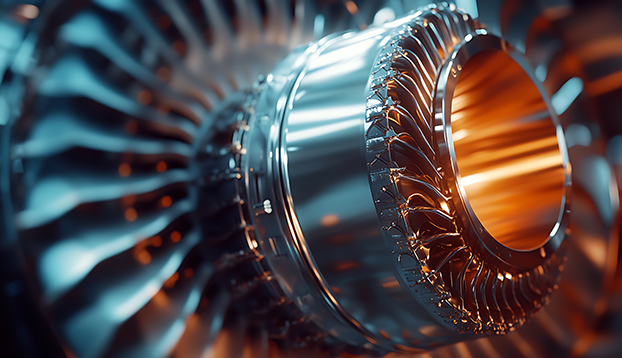

The main purpose of rotational performance testing is to verify the structural design, strength performance, working life, fatigue durability, and static strength of rotating parts. During product development, rotational performance testing can verify the strength performance and durability of the product under specific conditions and optimize material design. During product design, dynamic performance testing can ensure that the product will not fail due to fatigue during long-term use, improving the reliability and safety of the product.

Static/dynamic bird strike test for rotating blades, blade overspeed test, high/low cycle fatigue rotation test for blades, rotor blade-off test, rotor rotational dynamic characteristics test, rotor sudden imbalance test, casing containment performance test, bearing static strength/dynamic load/performance and life test, bearing slip test, bearing accelerated life test, fastener rotational mechanical performance test, seal rotational sealing performance test, pressure chamber rotational pressure resistance test, etc.

Bird Strike Test Rig 01, 02 Equipment Parameters

Speed range: 0 to 5,000rpm, 0 to 21,000rpm;

Rotating diameter: φ3,000mm, φ1,200mm;

Projectile weight: 100 to 3,600g;

Projectile diameter: φ16 to φ150 mm;

Projectile speed: 60 to 300m/s.

Bearing Fatigue Test Machine Equipment Parameters

Speed range: 0 to 18,000rpm;

Radial load: 0 to 110kN;

Axial load: 0 to 63kN;

Oil supply pressure: 0 to 5MPa;

Oil supply flow: 0 to 1,600kg/h;

Oil supply temperature: 20 to 200℃.