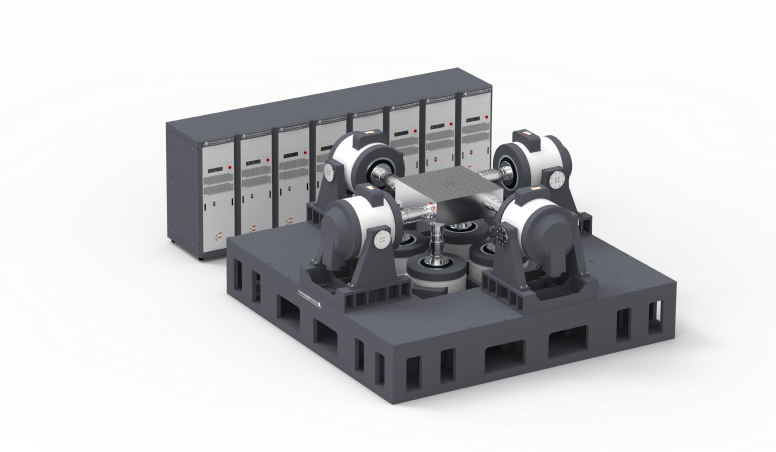

Highly Accelerated Life Testing (HALT)

Highly Accelerated Life Testing (HALT) is a method that applies stresses more severe than the normal operating environment to quickly precipitate latent defects in a product. It is used to identify weak links in the design and manufacturing process in a short amount of time, determine the product's operational and destructive limits, and provide a basis for design improvements, thereby enhancing product reliability.

We have various models of HALT and stress screening systems with 6-degree-of-freedom repetitive shock vibration and quasi-random vibration functions. The vibration frequency can reach up to 10,000 Hz, with a maximum acceleration of 100 g. These systems also feature rapid temperature change capabilities, with a rate of ≥60°C/min and a temperature range of -100°C to 250°C. We can perform temperature step, vibration step, and combined temperature-vibration step tests. For data acquisition, we are equipped with temperature and vibration data collection devices.