Accelerated Testing

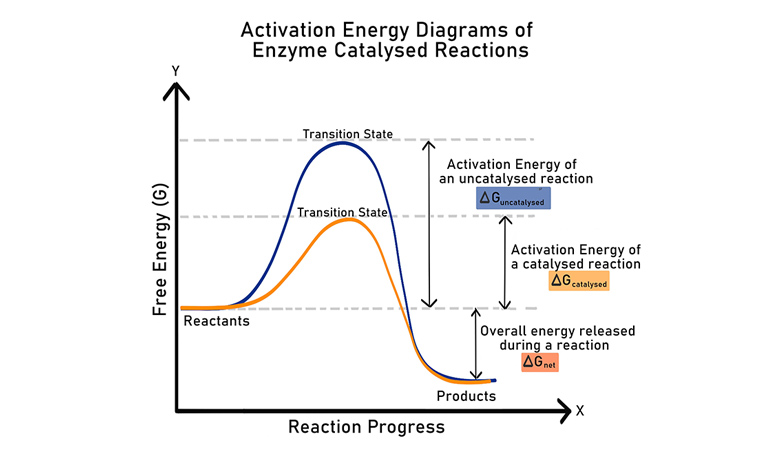

Accelerated testing is a method used to shorten test duration by applying increased stress levels without altering the failure modes and mechanisms. Compared to traditional testing, accelerated testing typically has a significant acceleration effect, capable of reducing test time by several or even tens of times, thereby improving test efficiency and reducing costs. It is an effective method for evaluating the reliability indicators of high-reliability, long-life products.

We have a professional team of reliability engineers proficient in various acceleration models, such as the Arrhenius, Inverse Power Law, Eyring, and Temperature Cycling models. We are capable of designing reliability acceleration plans and can provide targeted improvement suggestions based on the assessment results.

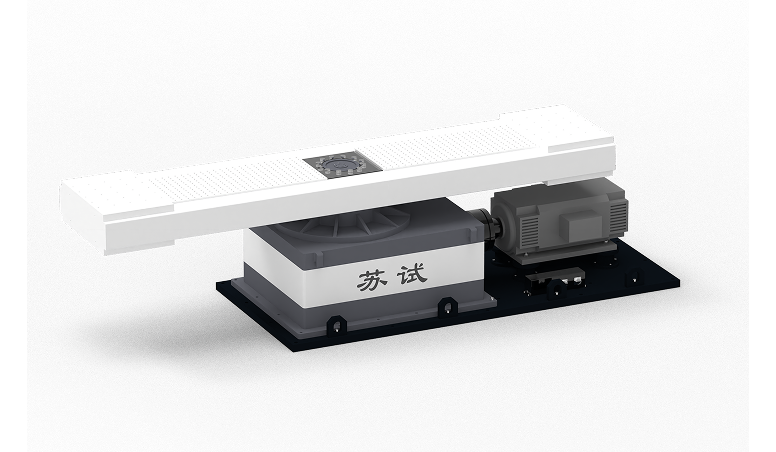

We are equipped with various specifications of freely combinable three-in-one environmental test systems, with the largest being a 25m³ system with a 40T (392 kN) shaker. For clients requiring larger systems, we can temporarily assemble up to a 40m³ system with a 60T (588 kN) shaker (internal dimensions 3,300mm×3,300mm×2,200mm). We are also equipped with high-power adjustable AC/DC power supplies and high-power resistive-inductive loads to meet the needs of applying electrical stress and operating under load during testing. Combined with our accelerated test design capabilities, we can significantly save test time and costs.