Drop Testing

The laboratory is equipped with professional drop test machines and related facilities to precisely control parameters such as drop height and angle. This simulates potential drops during handling, transportation, and use, allowing for the inspection of appearance and performance changes in the product and its packaging upon impact. It helps evaluate the product's durability and reliability, as well as the protective capability of the packaging. This assists manufacturers in identifying weak points and potential issues, enabling timely improvements and optimization of product and packaging design. We can meet the requirements of various products and test standards, including free fall, oriented drop, repeated drop, and rotational drop tests.

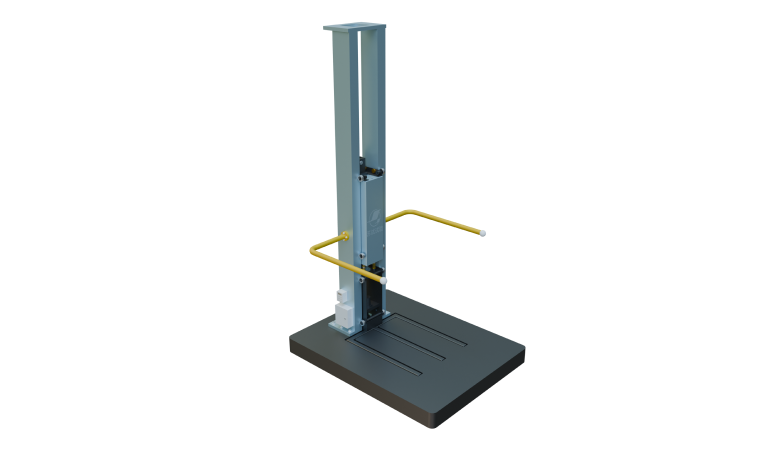

Conventional Drop Test Machine:

Max. Load: 300 kg;

Drop Height: 0 to 1,200 mm;

Impact Surface Size: 1800 mm to 2,000 mm.

Non-standard Drop Test Equipment: We can also conduct special quick-release drop tests from specified heights based on sample characteristics, with heights exceeding 10 m.

ISTA 1A, ISTA 1B, ISTA 2A, GR-63-CORE,etc.