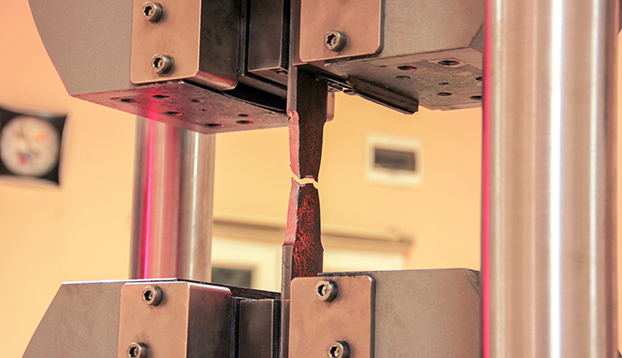

Material Mechanical Properties Testing

The mechanical state of a material under load is generally represented by various mechanical parameters (such as stress, strain, impact absorption energy, stress intensity factor, etc.). The corresponding relationship between these mechanical parameters under the action of external loads or the combined action of loads and environmental temperature is called the mechanical behavior of the material, usually characterized in the form of curves or equations. The characteristic values of these curves or equations (slope, inflection points, extreme values, asymptotes, and endpoints, etc.) are usually the characterization points of the material's mechanical properties. The critical or specified values of the parameters characterizing the material's mechanical behavior are called the material's mechanical performance indicators (such as yield strength, plastic strain, hardness, fracture toughness, creep strength, fatigue limit, fatigue crack growth threshold, etc.).

MTS test system, high-frequency fatigue test control system, electro-hydraulic servo fatigue test control system, dedicated metallographic image quantitative analysis system, creep rupture test system, and Brinell, Rockwell, Vickers hardness testers, impact testing machines, etc. We can test material's tensile properties, bending properties, compression properties, shear properties, impact strength, tear strength, hardness, shear strength, torsion, creep test, composition inspection, metallographic analysis, coating thickness, hardness testing, high-temperature creep rupture strength test, elastic modulus, S-N curve, P-S-N curve, material/structural fatigue, low/high cycle fatigue, tension-tension/tension-compression/compression-compression/torsion/bending fatigue, fracture toughness, crack growth rate, etc.