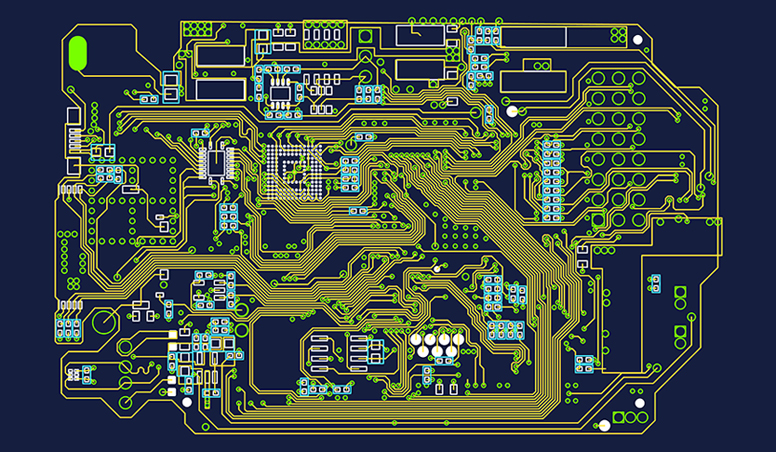

Circuit Design, Layout, and Debugging

In the process of integrated circuit (IC) reliability testing, the BIB (Burn In Board) is carried out, which stably connects the IC to be tested with the BIB through SOCKET or direct soldering, and then puts the whole into a professional test machine (such as HTOL). Within these machines, the ICs are subjected to a variety of rigorous environmental tests, including different temperatures, voltages, and signals, to simulate the operation of the IC in real-world applications. The purpose of these tests is to obtain the probability of failure of the IC at different stages of use. Through reliability testing, defective products in the early and late stages can be effectively screened out, so as to ensure that the IC products finally delivered to customers have excellent quality and reliability.

Functional test load boards, burn-in boards, stress boards, aging boards, high-temperature high-humidity test boards (HAST Board, THB Board), board-level reliability test boards (BLR Test Board), and the design, simulation, and fabrication of test sockets.