Mechanical Abuse

The main purpose of the crush test is to simulate the scenario where a battery pack undergoes severe deformation after a side collision of a vehicle. The drop test aims to simulate accidental drops of the battery pack during maintenance or installation. The simulated collision test is intended to simulate the dangerous scenario of a collision between vehicles when the battery pack is installed on the vehicle.

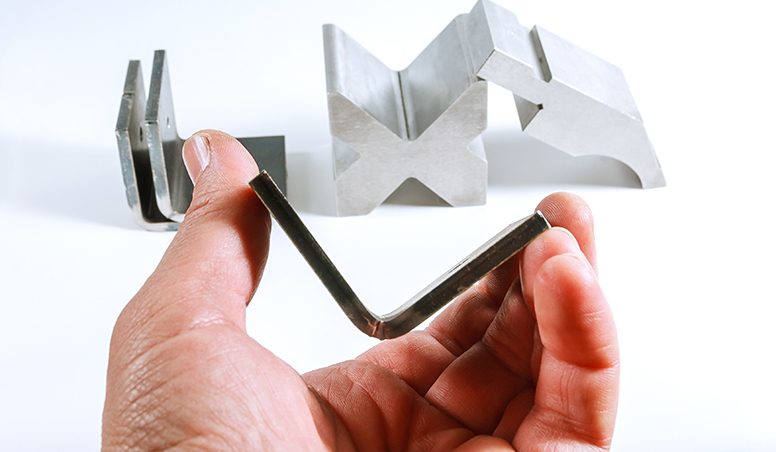

Crush, drop, collision, nail penetration, rollover, bottom ball impact, bottom scraping, bottom impact, etc.

The laboratory has a full set of crush and nail penetration equipment with a maximum crush test capability of 200 kN. The laboratory's drop test equipment has a maximum drop height of up to 1,500 mm and a maximum load of 1,200 kg. The simulated collision test equipment has a maximum thrust of 588 kN, a maximum load of 10,000 kg, and a maximum acceleration of 100 g.

1) Crush and Nail Penetration Equipment

Max. Test Force: 200 kN;

Test Stroke: 0-1,000 mm;

Crush Speed: 1-25 mm/s;

Nail Penetration Speed: 0.1-25 mm/s.

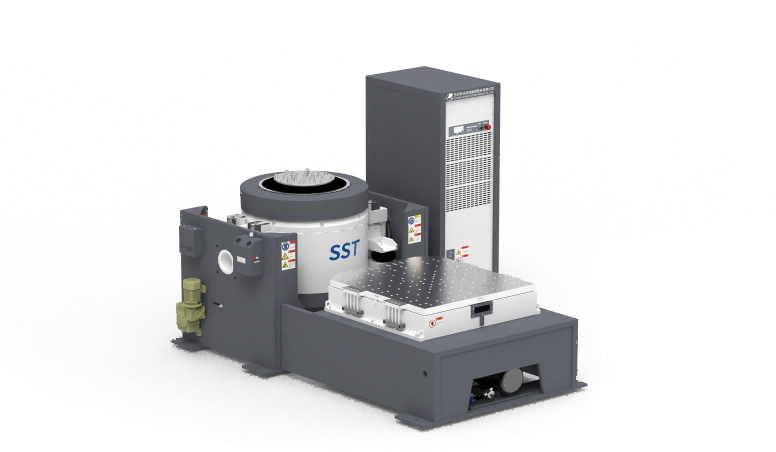

2) Collision Test Equipment

1. Vibration Frequency Range: 2-2,500 Hz, Max. Thrust: 392 kN, Max. Load: 4,000 kg, Max. Acceleration: 100 g, Max. Displacement: 51 mm;

2. Vibration Frequency Range: 2-1,500 Hz, Max. Thrust: 588 kN, Max. Load: 10,000 kg, Max. Acceleration: 100 g, Max. Displacement: 51 mm;

3. Half-sine, Terminal-peak Sawtooth: Pulse width ≤ 30 ms.

3) Drop Test Equipment

Drop Height: ≤ 1,500 mm;

Load: ≤ 1,200 kg;

Max. Specimen Size: 2,200mm * 2,200mm * 1,200mm.

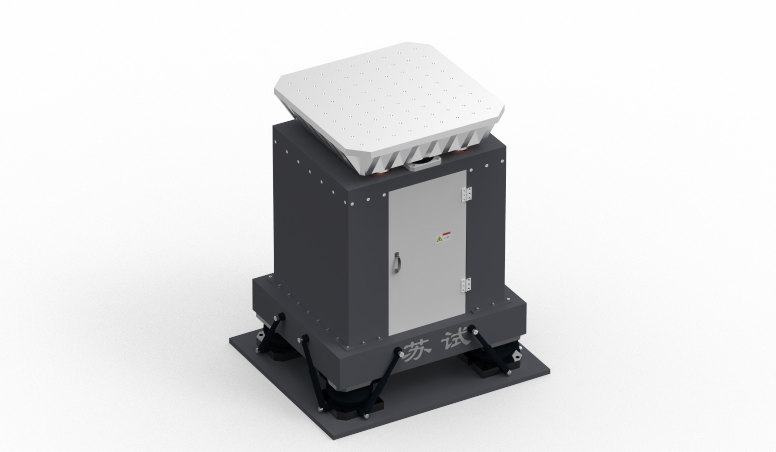

4) Rollover Test Equipment

Max. Test Weight: 1,000 kg;

Rotation Axis: X-axis, Y-axis;

Test Angle: 1-720°;

Rollover Plate Size: ≥3,000 * 20,000 mm (W*D);

Test Speed: 1-12°/s.

ANSI/CAN/UL/ULC 2580, IEC 60086-4, IEC 62133, IEC 62133-1, UN38.3(ST/SG/AC.10/11/Rev.7/Amend.1), IEC 62660-2, GR-63-CORE, ISTA 1A, ASTM-D4169, ISO 8092-2, ISO 16750-3, etc.